The burgeoning telecommunications, manufacturing, retail, healthcare, and financial industries are powered by an estimated 7.2 million data centers globally today. Hyperscale computing, the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), and 5G are all components of these modern marvels.

The data-driven global economy relies on data centers; therefore, they must have an intelligent, user-friendly system to monitor and control their assets. An accurate and dependable system is of the utmost importance due to the high volume of costly equipment that needs to be moved in and out for repair or reconfiguration, such as hard drives, servers, and individual IoT devices.

Asset underutilization, income loss, and worries about regulatory compliance are all outcomes of ineffective and out-of-date monitoring and asset management systems.

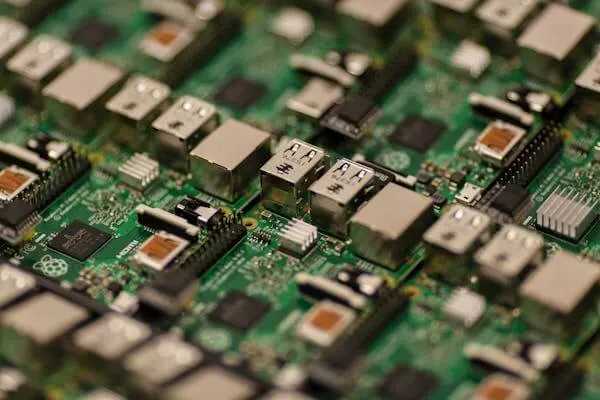

The process of keeping tabs on and evaluating all of a data center’s IT and network components is known as data center asset tracking. Racks, sensors, and sites in the network’s periphery are all part of the IT and network components. Integral to data center asset tracking is the monitoring of infrastructure power and cooling levels.

In contrast, data center asset management refers to the comprehensive approach to managing valuable data center assets. Obtaining vital inventory monitoring, controlling assets, holding organizations accountable, establishing critical procedures, and maintaining compliance are its primary goals. An essential part of managing assets in a data center is keeping tabs on them.

Just how does asset tracking function?

Teams use RFID (radio-frequency identification) technology to carry out asset-tracking activities.

Data centers may monitor their possessions by attaching radio frequency identification (RFID) tags to specific items and reading those tags using specialized reader gear. The data is then processed to monitor and control these assets.

Data transfer

Passive and active RFID tracking systems are available. Their transmission, frequency, read range, tag size, lifetime, attachment technique, and cost vary, but they both use the same fundamental technology.

With no moving parts and a solid-state design, passive RFID tags can last indefinitely without deterioration. Due to increased operating frequencies and continuous use, the typical lifespan of an active RFID tag is three to five years.

1. Passive RFID Tags

Passive radio frequency identification tags consist of a substrate, an antenna, and a chip.

The data stored on the chip can be read-only (RO), write-once (WORM), or read-write (RW), depending on its architecture. There is a memory range of 2–1000 bits.

Its Reflector antennas are used for data transmission and reception by drawing in radio-frequency (RF) waves from reader signals. The capacity of a passive RFID tag is proportional to the size of the antenna.

The substrate is the third component of the tag and is responsible for attaching the chip and antenna. It is like the “glue” that keeps everything together.

Using RFID tags with low frequencies and limited ranges allows for passive asset tracking.

2. Active RFID Tags

In addition to the antenna, active RFID tags include a microprocessor. On the other hand, active tags often have smaller chips with more capacity than passive tags. When it comes to long-range RFID tagging, active tags utilize Bluetooth, low-energy, high-frequency, or even ultra-high frequency. They differ from passive tags in two ways: first, they include electronics and power sources built right in.

Power Source for the Ship Solar panels or batteries can be used as the power source. Thanks to its power source, the tag can communicate with a reader autonomously; unlike passive tags, active tags do not require electricity from the reader to function. Passive tags have a maximum reading range of around 20 feet, but active tags have a range of 100 feet or more.

Electronics on Board Sensors, microprocessors, and input/output ports are all examples of the onboard electronics the tag’s onboard power source can power. Due to their electrical components, active RFID tags have more potential uses than their passive counterparts.

Reading Range and Frequency

Although passive RFID tags may have their uses, they simply cannot keep up with the demands of today’s data centers.

Outdated asset-tracking solutions just can’t cut it in today’s mission-critical data center environments. Even more crucially, there is a substantial possibility of loss or mistake in manual operations. According to IT asset managers, companies that still rely on antiquated manual methods of asset monitoring and inventory, such as passive RFID technology, barcode scanners or clipboards, and spreadsheets, often have an average inventory error of 15% each year.

In what ways might asset management and tracking be advantageous?

The CenterScape platform from RF Code allows IT asset managers to monitor critical metrics, such as location, temperature, and more.

1. Boosts productivity

Data center assets, such as servers and hard drives, must be physically removed from rack servers for routine maintenance. It is easy for employees to lose track of or incorrectly classify these assets after they are presented to the service department. The time it takes for IT administrators to find misplaced servers or hard drives may be significantly cut down using digital asset tracking.

2. Enables proactive asset monitoring.

In addition to making it easy to find misplaced items, data center asset tracking also lets IT staff keep tabs on vital equipment states like power and cooling levels.

3. Makes monitoring work-in-progress easier.

IT administrators must remain vigilant throughout data center operations, from setup to routine maintenance. Because RFID tagging gives real-time work status updates from the floor or the field, data center asset tracking eliminates the need for IT managers to depend on guessing.

4. Reduces audit complexity significantly.

Data center asset monitoring entails a precise inventory of data center assets, including precise position information. Manual inventory techniques would be an enormous undertaking. Digital asset tracking systems streamline auditing procedures and eliminate time-consuming and money-wasting human mistakes.

5. Better compliance is the result of enhanced audits.

The ever-changing landscape of energy efficiency and compliance mandates underscores the need for data centers to follow operational best practices. By implementing a digital data center audit system, compliance concerns can be promptly handled before they escalate into serious compliance hazards.

In the end!

Real-time asset tracking provides various benefits for businesses, including improved visibility, security, efficiency, and compliance. A reliable company’s knowledge and products would help companies maximize these benefits, which, in turn, drives growth and success.

Jessi is the creative mind behind The Coffee Mom, a popular blog that combines parenting advice, travel tips, and a love for all things Disney. As a trusted Disney influencer and passionate storyteller, Jessi’s authentic insights and relatable content resonate with readers worldwide.