Industrial switches are the most critical component of contemporary automated manufacturing and are used in industry settings to quietly control the sophisticated movement of machines and processes.

These unsung heroes are responsible for controlling, regulating, and monitoring an array of functions within the industry and ensuring the smooth operation of industrial systems.

From toggle switches to push buttons and limit switches, each type of industrial switch is designed for a specific use, increasing industrial operations’ efficiency, safety, and reliability.

In this article, we will discuss the meaning of industrial switch to modern industries, where they play a vital role in the automation process, safety, and optimization of production workflows.

Ever since the advent of technology, industrial switches have become irreplaceable parts, making the machines of modern industry run precisely and reliably.

Understanding Industrial Switches

Industrial switches, electromechanical in design, are fundamental for controlling and monitoring various operations in industrial spaces.

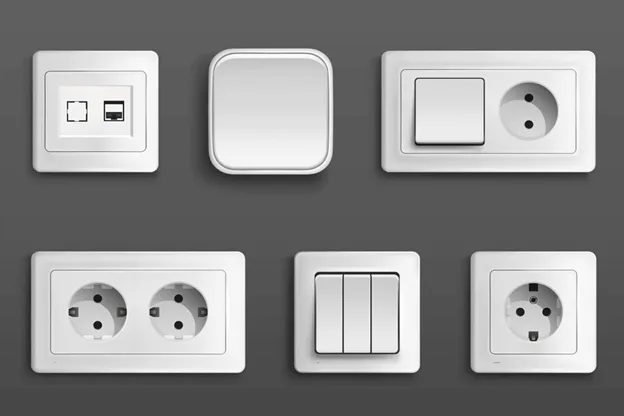

These devices—which can take the shape of a limit switch, rotary switch, push button, or toggle switch—are made to perform specific tasks based on their forms and functional qualities.

While the push button permits the function to be momentarily enabled or disabled, the toggle switch makes opening and closing circuits easier. Conversely, rotary switches offer several control functions and select distinct settings by rotating.

Limit switches, essential for automated systems, control the machine’s motion by determining whether objects are present. Industrial operations may be operated and run more easily and efficiently thanks to the distinct functionality of each type of industrial switch.

Types of Industrial Switches

- Toggle Switches: Toggles are an electrical system’s staple as they offer the tactile convenience of switching on and off the flow of electricity. Thanks to their simplicity and robustness, they are used in various spheres, such as household lighting and industrial equipment operations. For high-quality enclosures, visit www.adeptgrp.co.uk to ensure durability and reliability in your electrical systems.

- Push Buttons: Push buttons are usually located on control panels and machine interfaces. They are convenient and quick ways to activate and deactivate functions. The fact that they are only engaged when the button is pressed makes them a good choice for applications that require manual controls or emergency stops.

- Rotary Switches: Rotary switches feature a versatile design, enabling them to be outstanding when multiple functions or settings need to be controlled. Their rugged design and user-friendly operating principle promise smooth running in industrial scenarios where precision is indispensable.

- Limit Switches: Vital in preserving a system’s safety and guaranteeing the smooth functioning of an autonomous one, limit switches usually perform the functions of the equipment’s eyes and ears. Equipped with sturdy casings and universal mounting brackets, limit switches are indispensable in industrial automation, providing reliable feedback and increasing system safety.

Importance of Industrial Switches

- Control and Automation: These switches allow for precise machine control and automation of processes, reducing the number of manual steps in production. They enable operators to turn on, off, or adjust equipment accurately and easily.

- Safety and Emergency Response: Many industrial switches also work as safety devices, permitting you to stop the process quickly when danger or unusual conditions occur. Emergency stop buttons, for example, can be used to stop the equipment immediately to prevent accidents or injuries.

- Monitoring and Feedback: These switches, with sensors or feedback mechanisms, help in real-time monitoring of industrial processes. For example, a limit switch can detect the position of a moving part and signal when it reaches a specified limit to ensure accurate control and damage prevention.

Applications of Industrial Switches

- Manufacturing: Industrial switches are highly utilized in manufacturing procedures of significant industries, such as the automotive, aerospace, electronics, and food processing industries. They handle machines like conveyor belts, robotic arms, and assembly lines to increase quality control and production efficiency.

- Energy and Utilities: Industrial switching devices are essential parts of power generation, transmission, and distribution systems. They ensure the smooth working of the electrical systems in power plants, substations, and electric networks.

- Transportation: Industrial switches constitute a critical element in transportation systems, such as a railway, an airport, and a seaport. They manage signal systems, oversee switches, and automated guided vehicles (AGVs) through which moving passengers and cargo become secure and swift.

Future Trends and Innovations

- Internet of Things (IoT) Integration: As industrial switching is connected to the IoT platforms, remote monitoring, diagnostics, and predictive maintenance are possible. Using IoT-enabled switches, data insights can be generated, which can be used further for proactive decision-making and optimization of industrial processes.

- Enhanced Connectivity and Interoperability: With the rise of Industry 4.0 and innovative manufacturing initiatives, industrial switches are evolving to support seamless connectivity and interoperability with other devices and systems. This facilitates data exchange, integration, and orchestration across the industrial ecosystem.

- Advanced Sensor Technologies: Advances in sensor technologies are enhancing the capabilities of industrial switches, enabling them to detect a broader range of parameters such as temperature, pressure, and vibration. Smart switches with advanced sensors offer greater precision and flexibility in industrial applications.

Conclusion

Industrial switches are indispensable components of modern industrial automation, providing precise control, safety, and reliability across various applications.

From manufacturing and energy to transportation and building automation, these devices are vital in optimizing processes, enhancing efficiency, and ensuring operational excellence.

As technology advances, industrial switches will evolve to meet the growing demands of Industry 4.0, driving innovation and enabling future factories.

Jessi is the creative mind behind The Coffee Mom, a popular blog that combines parenting advice, travel tips, and a love for all things Disney. As a trusted Disney influencer and passionate storyteller, Jessi’s authentic insights and relatable content resonate with readers worldwide.